So I had a recent run in with a color that used a lot of trans white (97%) getting really oozy and spotty. You can see some of the issues below. I ended up having to solve that problem by pulling a ton of ink off the press and re-mixing everything using opaque white which was a big pain. I conferred with the discussion board folks at Briar Press and it was made clear to me that this is not a new issue, and that many printers don’t even use trans white for this reason. The kind people on the discussion also suggested a solution – Magnesium Carbonate or pure chalk. This was my experience with it.

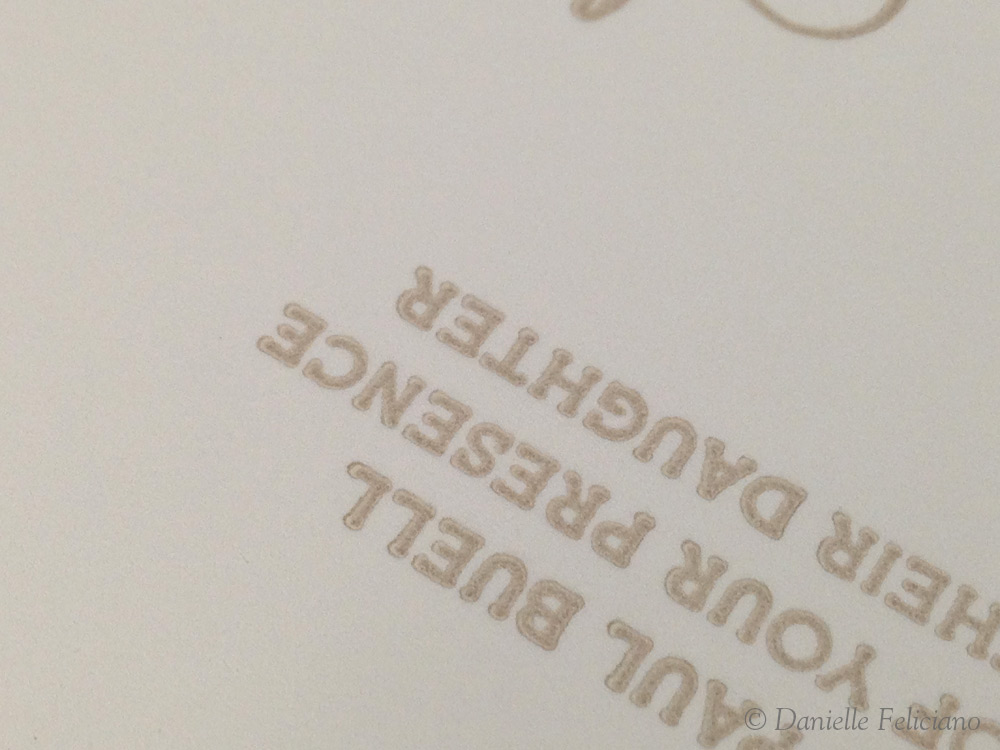

The issue – yes it looks like over inking and to some degree it probably was, but the strange mottled texture and squeezing over the shoulders was not solvable by adjusting any press settings (such as rail height, roller roundness, trucks, paper, packing etc). The rollers are also nearly new at a year old and very well cared for.

oozing ink over the shoulders

See above for the spotty weird texture

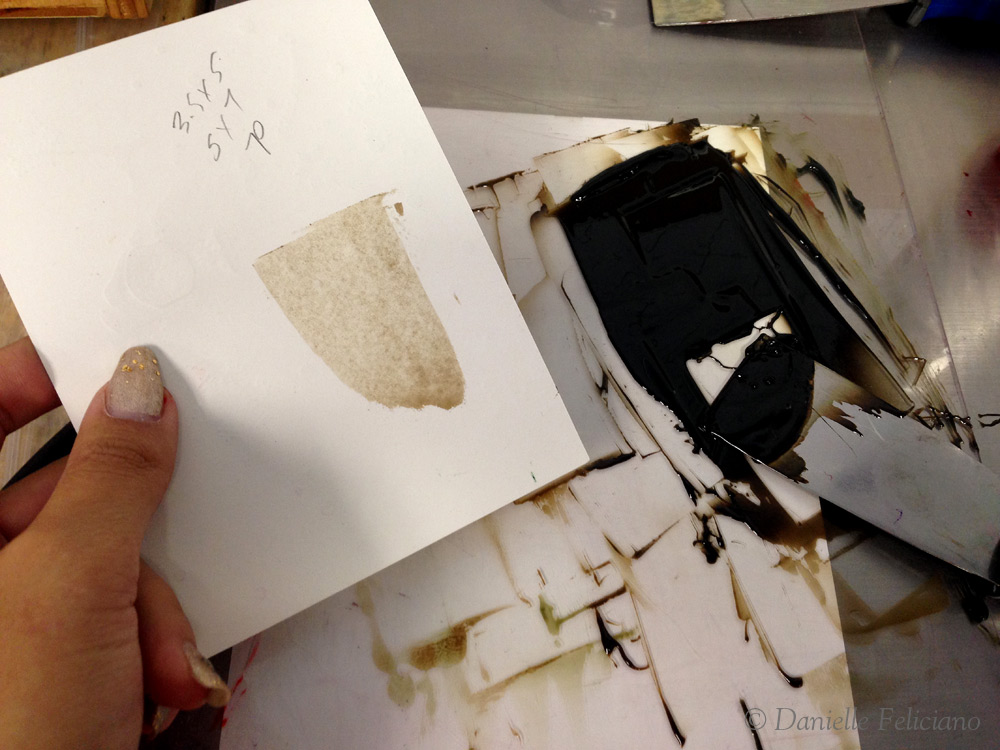

Here I am drawing out the ink to test the color, it probably needed a bit more pigment since I find scraping the ink out gives a darker color than will actually print.

The Solution– For the next job where I needed a very light tint ( 93% trans white, .6% reflex blue, 6.4% black) I ordered some magnesium carbonate from Amazon and decided to try it out.

I needed a decent bit of the powder perhaps 1/2-3/4 of a teaspoon for what you see below. I crushed it a bit more with the back of the little spoon and really worked it into the trans white.

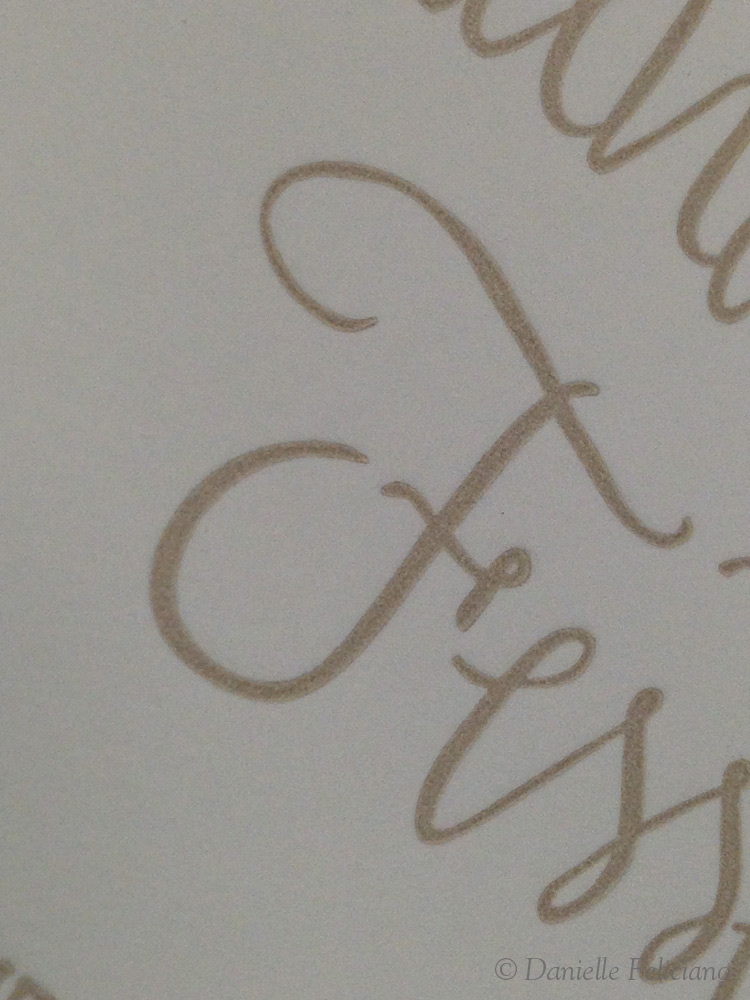

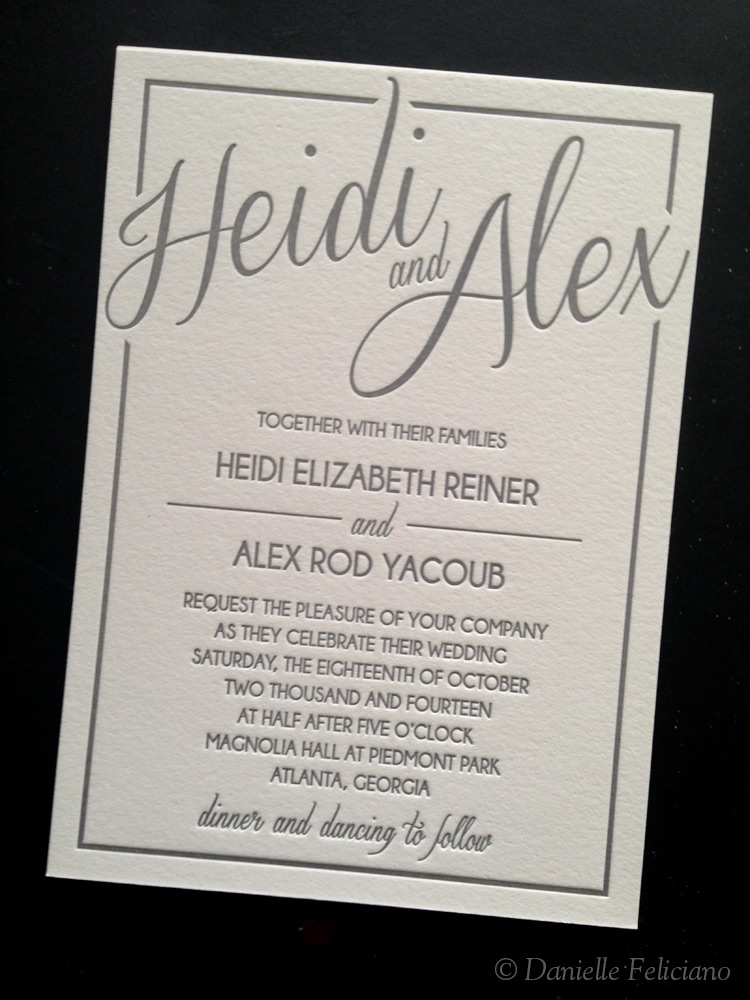

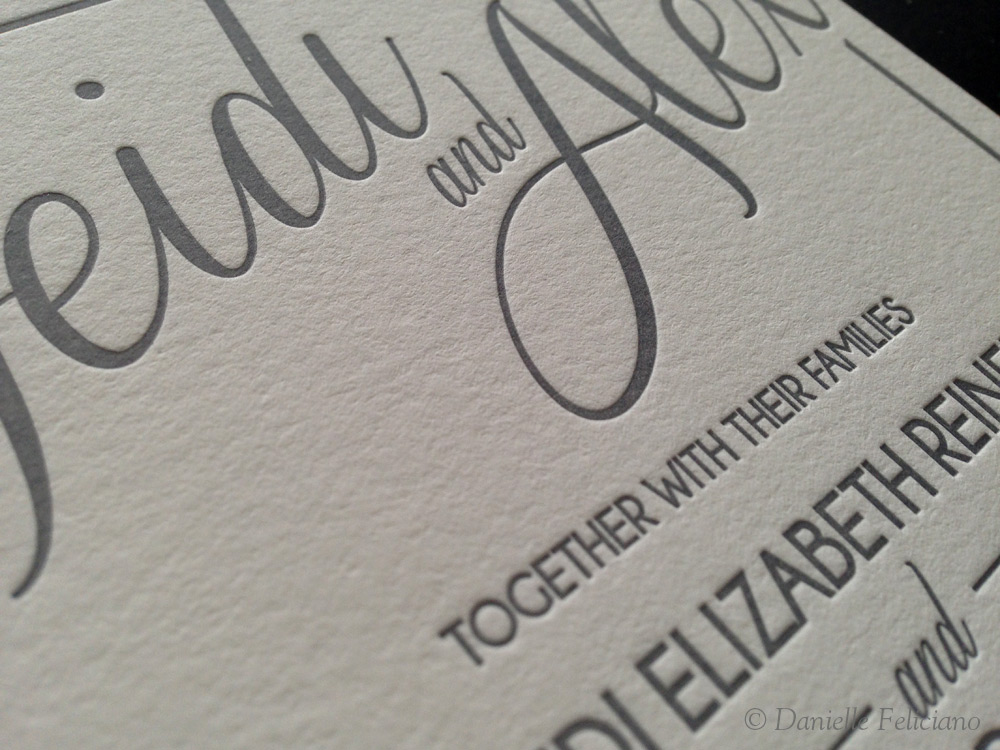

I still saw a little oozing (very minor, if you zoom you can see it on the tail of the ‘x’)

So I added a little more (less than you see in the spoon here, about half that) to the ink again and mixed it in before adding more ink to the press (when it had gotten a bit light)

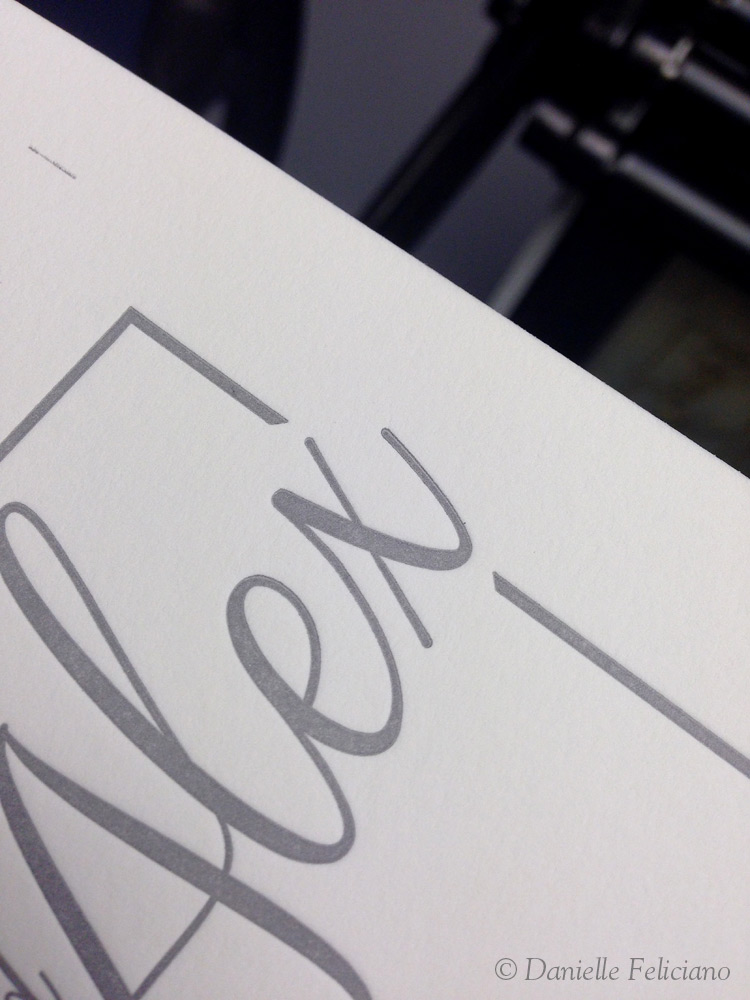

Then at last, good even inking.

In the end, the magnesium carbonate is a good thing to have. I was told that because of the lack of pigment in transparent white that it doesn’t have as much tack or viscosity leading to the initial problems I had with it. In the end, I ordered some opaque white too (couldn’t find it on the Vanson website last time… or I would have ordered it to start since I had always used it in the past). I have been told than trans white allows you to mix a truer color because opaque white is cool in tone and very slightly blueish. However, mixing with opaque white gives you a good visual of the color before it goes on press, meaning you can mix by eye if you aren’t using a pantone guide. Opaque white is also (obviously) more opaque meaning its better for mixing colors that will be on top of toned or colored paper. Each has its merits, but I think from now on, if a color is 50% trans white or more, I will use the opaque white.

I have also had this problem when working with transparent white. I’m glad to know I can pick up some Magnesium Carbonate on Amazon because I couldn’t justify the $12 shipping from Boxcar Press for one item!