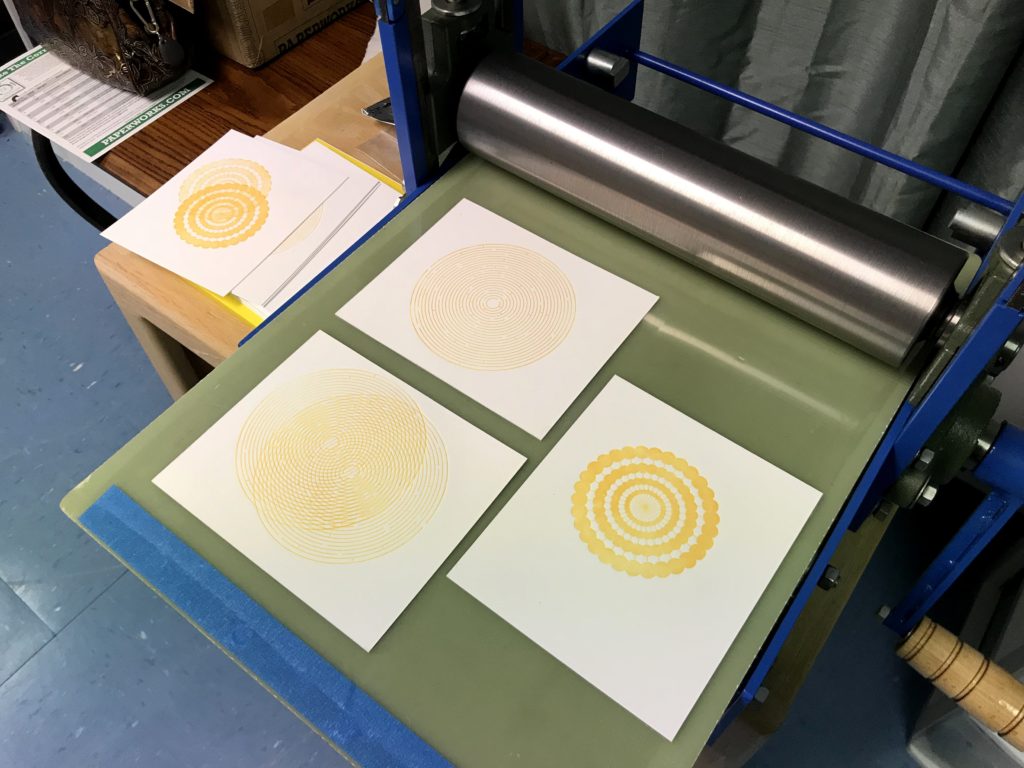

I wanted to do an update on the mini-press. Here is a second attempt at using photopolymer for relief printing.

In the last post I did some quick yellow prints, but for this print I wanted to try and add a second color.

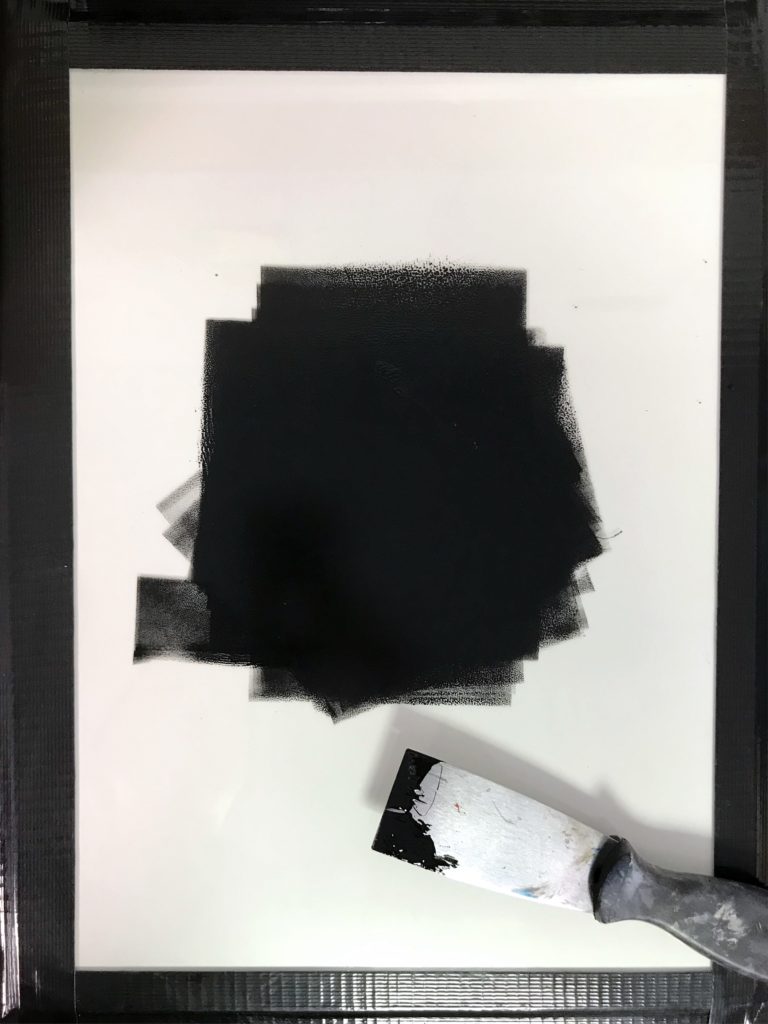

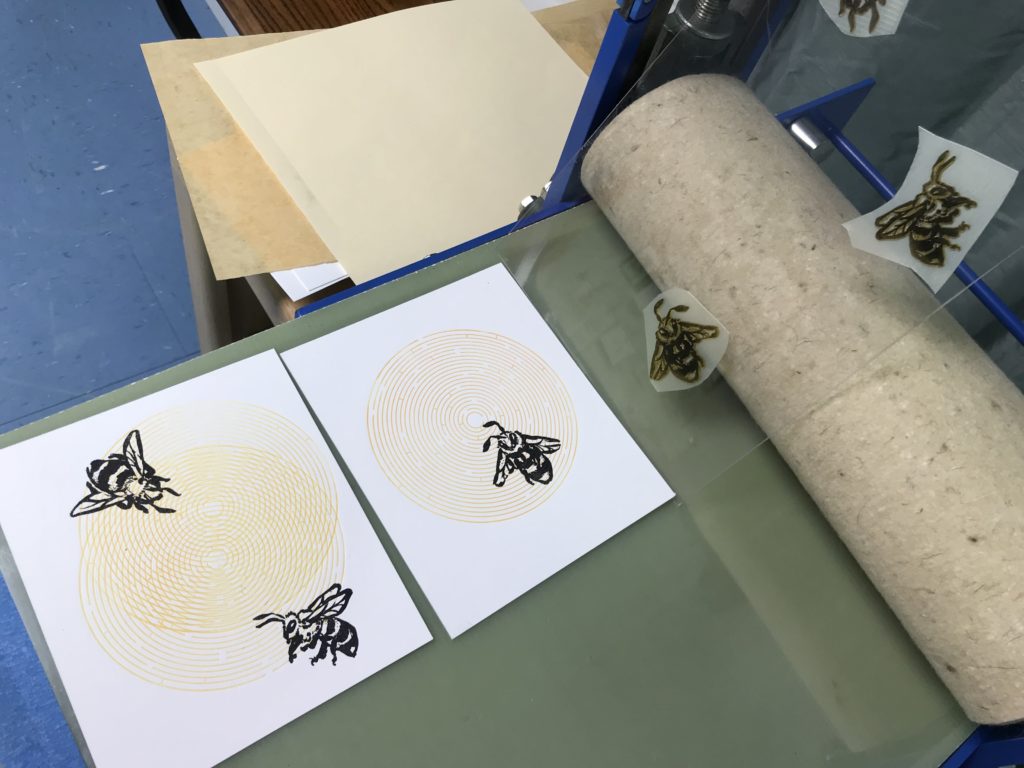

I’ve set up a new ink plate – this one is a spare piece of glass duct taped to my make ready station.

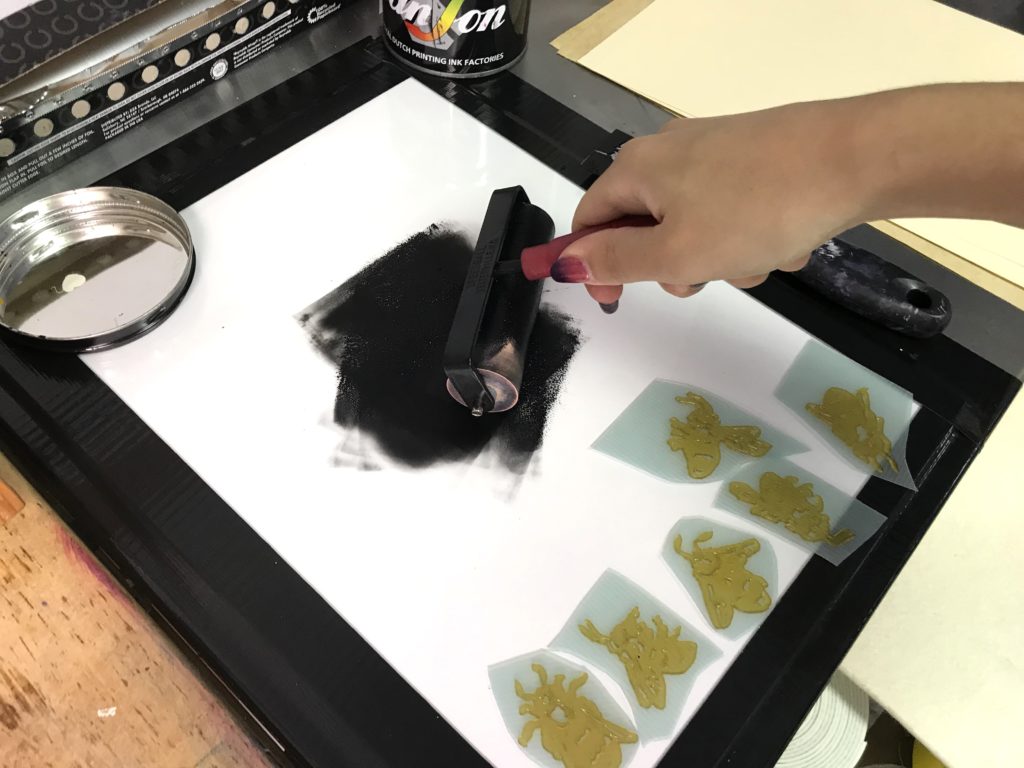

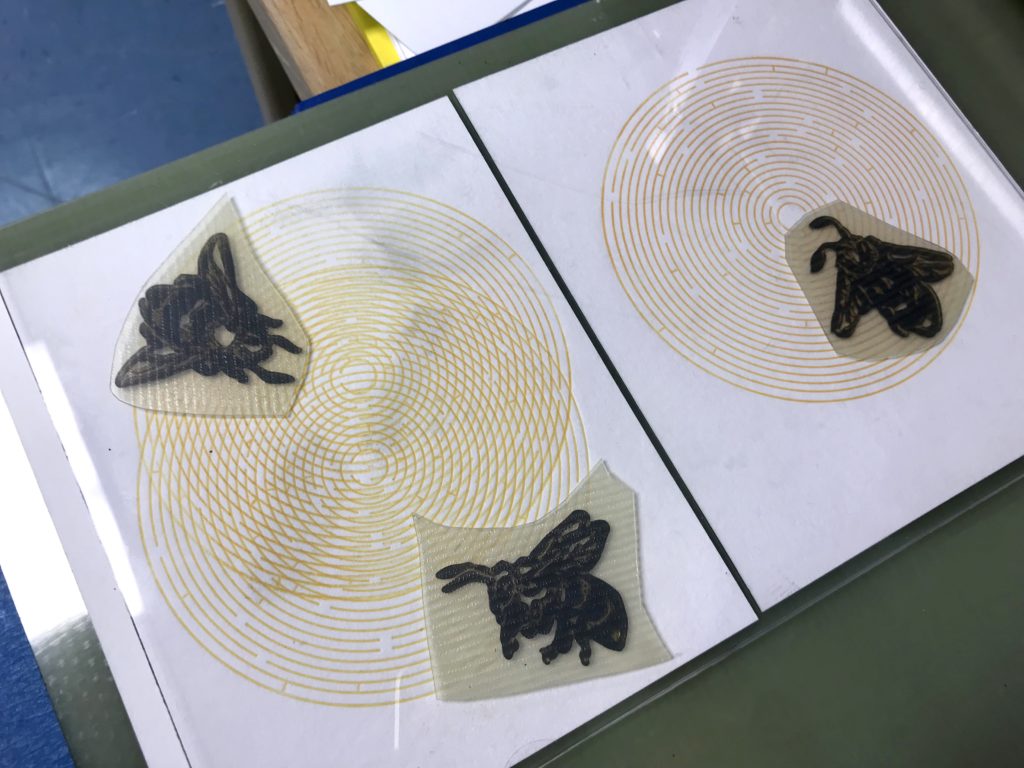

For this set of prints I tried a few different methods of printing the plates. I tried putting the plates underneath the paper and on top. For this press I’ve discovered these small photopolymer designs will print best if they are applied to a clear plate and placed face down onto the paper. This helps prevent shifting and keeps the pressure more even.

This has the advantage of letting you see the placement best as well. After inking up you need to carefully wipe any excess ink from the plate.

To keep the plate from sliding around when I ink, I’ve put it on a seat grip that I bought from the dollar store.

I was still having some issues with the edge of the photopolymer leaving an impression. I think it will take a little more finessing to get this right. An easy solution would be to just not cut the photopolymer down into small irregular shapes but instead keep in nice rectangular plates. I’m cheap so… that didn’t happen this time around.

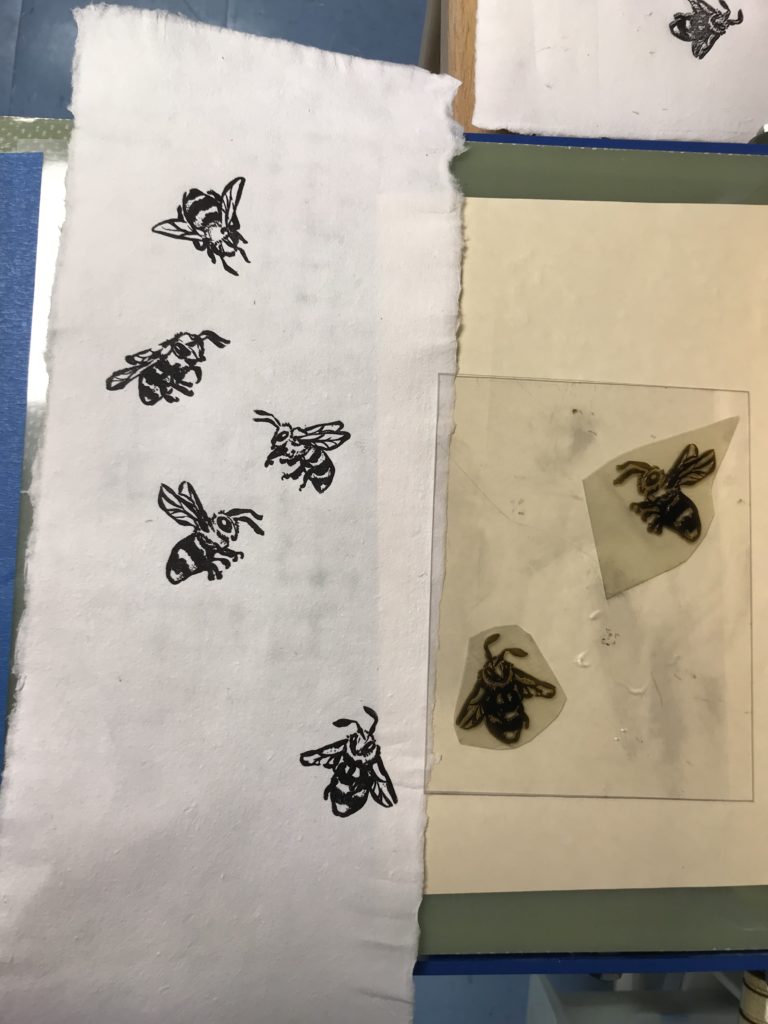

I also tried some handmade paper.

The tympan paper helps protect the blankets as well as smooth the pass through the press.

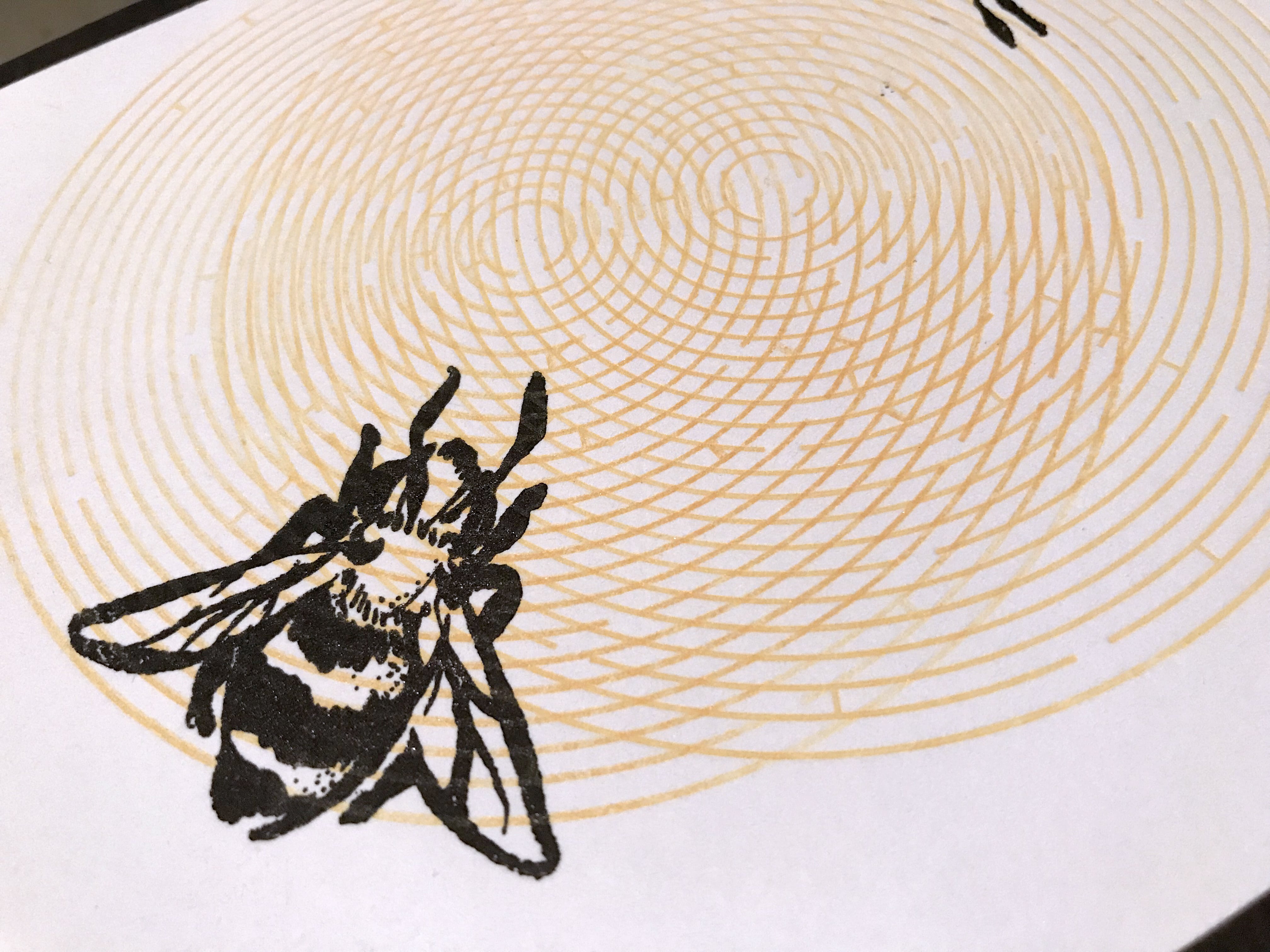

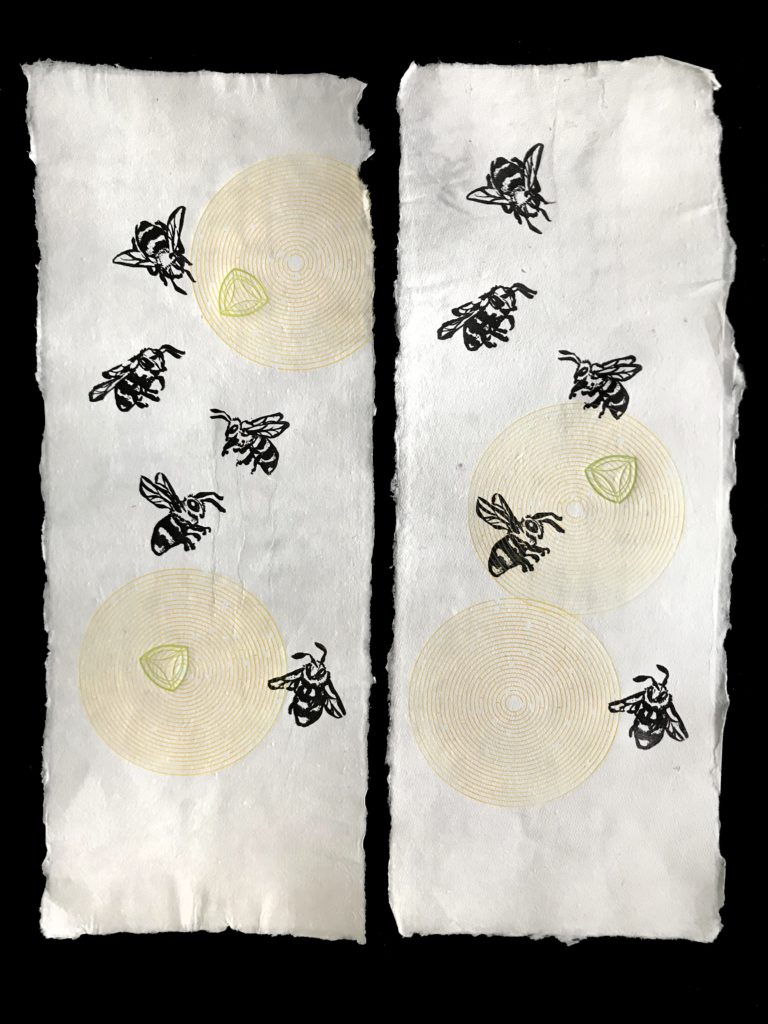

These are some shots of the final prints.

I think I’d also like to set something up with roller bearers to prevent having to spend so much time wiping the plate. It’s really easy to over ink the photopolymer – the impressions are a little heavy, but overall this technique definitely has potential.

Some things I’d suggest:

- Dampening the paper would probably remove some of the graininess of the print.

- Roller bearers will help get lighter more even print.

- Watch how you cut your edges as you might see them in the prints.

- Use the stickiness of the plates to your advantage – you can arrange your plates on acrylic plates to help you line up or apply them directly to the press bed.