Duplexing Tutorial Part 2 – Well, as a way of following up my previous post, I’m trying a second method of duplexing – one that fuses printed stocks of two colors. ILet me tell you though, the hardest part of duplexing by hand is the trimming (which is slow because my stack cutter is terrible) and the most tedious part is the gluing. It took me about eight and a half hours to duplex all 400 of these suckers. That doesn’t include the scoring which was another two hours. It’s not something my small press could offer for more than 500 unless they were doubled up in the printing stage. I also strongly suggest only doing this with designs that don’t require hairline alignment to the corners or edges the way this one does. Any minor errors are more obvious with a design like this. If you didn’t read part one see it HERE.

For this method I used the following steps:

1. Print both stocks (obviously) For these one side is 300gsm Crane Lettra and the other is a paper called Colorplan in Azure

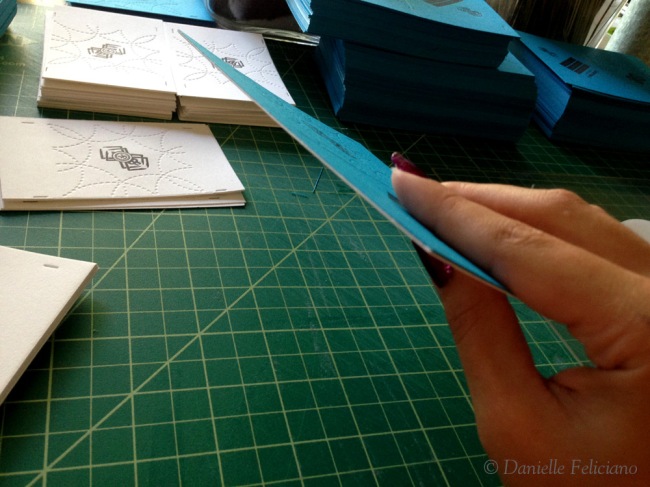

2. Just like my last post, I applied my glue with a roller to one sheet. You can see the impression level here

3. I lined up the bottom edge being sure the correct graphic was lining up with the correct back

4. I smoothed them together and there we go. The advantage of this method is that you are completing two cards at once. The disadvantage is that the line up is less sure than the scoring method. I would not offer this method to a client if there were very noticeable elements that would give away a slight hairline misalignment. In this job the bleed on both sides needs to line up with the corners and that was a challenge, but I wanted to test this method with a difficult job to see the limitations.

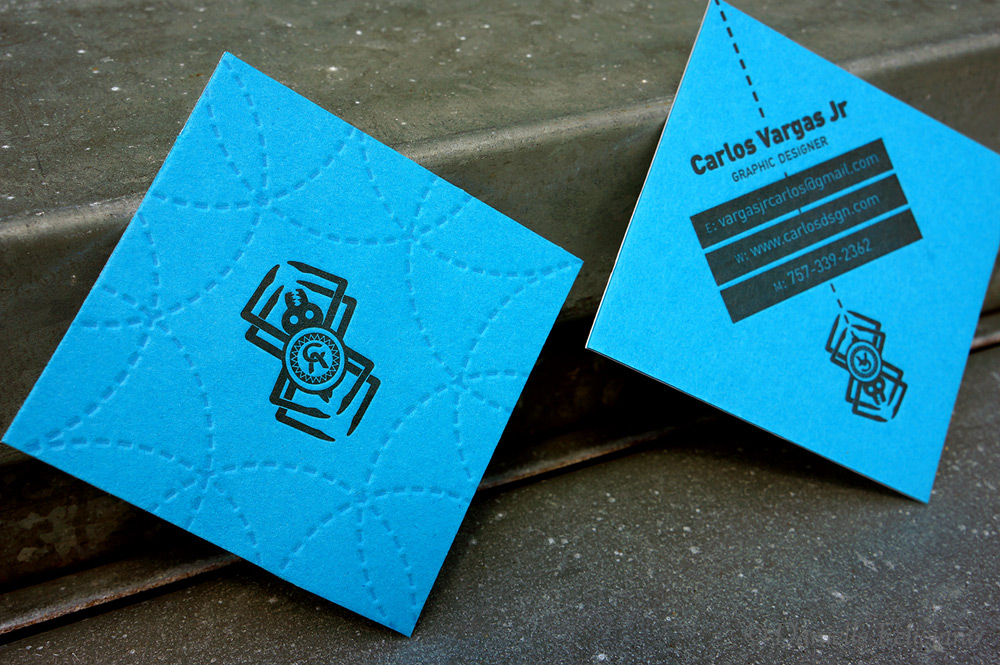

5. In the end, this method worked nearly as well as the folding method – however it should be noted that this worked so well because the images printed on the white (back side), and the images printed on the blue (front side) are printed in EXACTLY the same spot on the card (which were the same size). If they weren’t, they would need to be cut down to a primary set of guides and then trimmed again once they were glued together. Some came out a bit wonky, but for the most part, both sides lined up properly (below I accidentally photographed a crooked one… so just trust me on that). Here is the final result:

* The design on these cards is done by Carlos Vargas

I think my Lego jig (https://whynoteight.wordpress.com/2013/01/25/a-boxmaking-jig-or-stealing-toys-from-children/) would help you line things up.

Really smart, I’ve made many a jig, but never though to use legos for those corners haha!